What is CNC?

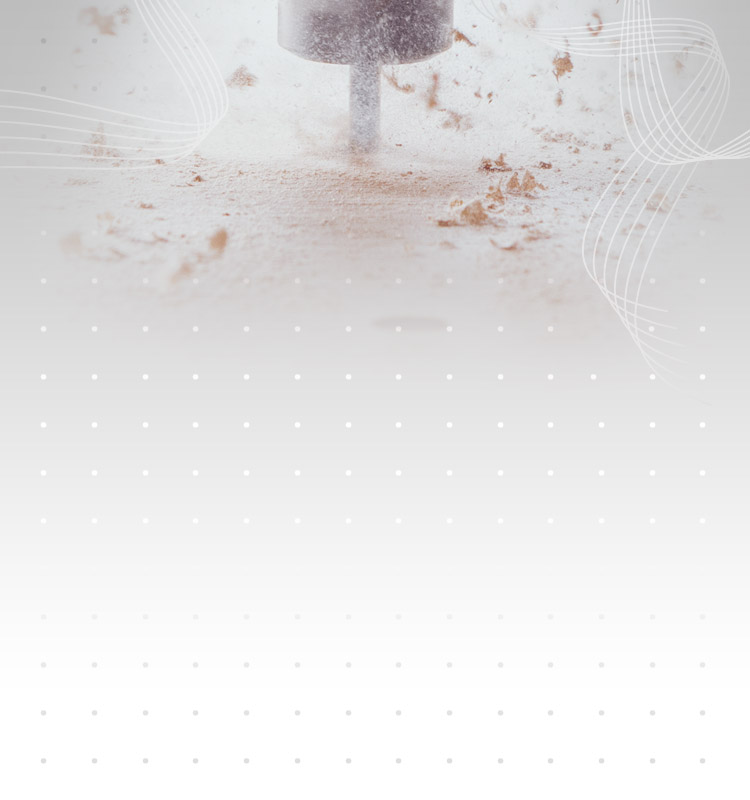

CNC stands for Computer Numerically Controlled and effectively means that the physical movements of the machine are controlled by instructions, such as co-ordinate positions that are generated using a computer.

The term “CNC Machine” is typically used to refer to a device that uses a rotating cutting tool which moves in 3 or more axes (X, Y and Z) to cut-out or carve parts in different types of materials. The information below will focus on what are typically referred to as “CNC Routers” although it would be applicable to most CNC milling and engraving machines too.

Compare features and pricing for all of our products

What can you make with a CNC?

CNC’s are incredibly versatile and allow you to cut a variety of different types of product and materials. The exact abilities of a machine will vary with size, rigidity and power. Typically most CNC routers can cut soft and hard wood, plastics, other composites and non-ferrous metals.

CNC users range from hobbyists who build their own machines through to large companies with industrial equipment costing hundreds of thousands of dollars.

With the right software a CNC can make a huge selection of things.

- Signage & Wall Art

- Custom Furniture

- Plaques

- Molds

- Toys

- Lithophanes

- Clocks & Picture Frames

- Mantels & Archways

- Prototypes

- Chests

Where does Vectric fit into this process?

Although a CNC Router is an amazing piece of technology it will not do anything unless it receives instructions. Vectric software is designed to create the instructions (toolpaths) to tell the CNC how to move to create your projects.

Collect Ideas, External Design work or data

In Vectric software:

Create 2D & 3D* Designs

Generate Toolpaths and Simulate in 3D

Export Toolpaths ready for cutting

Transfer the Toolpaths to the CNC Control PC to load into CNC Control Software

Prepare the Machine with correct Tooling and Material to cut

Run the CNC