Being able to turn a design that you have envisioned into reality takes quite a bit of skill and patience, especially when you are taking an “everyday” item and wish to put your own stamp on it. Well this is exactly what Doug Pinney had done when making his Pelican Box. You may have come across his project on the forum as it has proven quite popular with the Vectric community. Before we get a look at this fantastic project and why he made it, we wanted to find out about Doug’s background and how he got into CNC machining…

I retired from my job about 10 years ago now, and gosh the time has flown. I had worked in the construction industry where I was the Design/Build General Contractor, working on large scale commercial buildings. Once I retired my wife suggested that I finish my wood shop… it was one of those personal projects that kept getting pushed back due to work. After about 4 years I started looking for a new challenge in woodworking. This is where CNC machining came into my life.

I had seen some of the things you could do with a CNC machine, but it wasn’t enough to influence me to purchase one. I spent about 6 months researching some more. When I was at the point that I was ready to purchase one, I set myself 3 questions to ask each manufacturer. “Is your machine American made?”, “Do you have aftermarket support?” and “Do you have aftermarket training?”. These questions led me to purchase a Legacy Arty 58 CNC, then a 3x5 Maverick. Legacy was the only CNC manufacturer that answered my 3 questions with a yes.

I now I have a Legacy 4x8 Maverick CNC in my 4000 square foot work shop. I still like to incorporate my other traditional tools like saws, sanders and planners. The CNC is fitted with a good dust collection unit, it helps a lot when its time to clean up.

Legacy were really helpful when purchasing and setting up my CNC machine. They recommended Vectric software to me from the start. Currently I am using Aspire V9.5 . Two of the best things about Vectric for me are one, the ease of use of the entire product, especially the tools they have for 3D modelling and sculpting. Two, I really enjoy going to the Vectric User Group Meetings, they are usually around October.

It’s very clear from Doug’s journey to the present day, he has always made informed choices to make sure he has the right equipment to turn his designs into physical items. Located in his massive workshop, with his copy of Aspire we had to ask him about the Pelican Box project we couldn’t help but see on the Vectric forum…

My daughter really likes Pelicans, and her birthday was coming up so I decided I would make her something special which incorporated her favourite animal.

The design portion took months to get right. I kept tweaking the design, it just wouldn’t “sit” right. I do not like to make square/straight line projects. I love the look of soft curves and shape in my work, I think it adds another layer of personality and character to the finished piece. This was the part of the project I enjoyed the most. Using the modelling and drawing tools gave me so much freedom to fine tune my design to get the correct shape.

This project was made out of American Black Walnut which I got from the hardwood supplier. It’s really handy that I have quite a few different types of tool bits at hand in my workshop because this project used 5 different tools – 0.25 end mill, 0.25 ball nose, 0.125 ball nose, 0.0625 ball nose and a 0.25 60-degree v-bit.

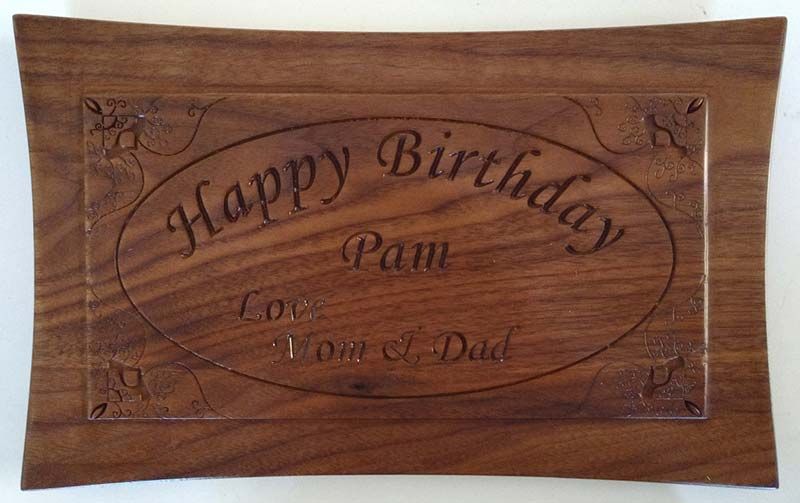

This project was so enjoyable to make from start to finish. I wouldn’t change anything so I don’t have any words of warning to share. But I do have some advice for you. Just let your mind wander when designing. Do not rush your design, let it come together. The best thing I can say is don’t be afraid to get up and walk away from the project, then come back to it. I can almost guarantee you that you will see the project in a different light. Oh, and also, don’t be afraid to use some clipart from Designandmake.com, its so easy to use. Purchase something you like, and simply drag and drop it into your design. After a few little tweaks your design has completely transformed.

I think we can all agree that Doug has a real care and eye for fine design and implements this in every stage of his process from the initial idea right through to finishing. We would like to take this opportunity to thank Doug for giving up his time to share his story with us. We can’t wait to see what future projects he shares with us…

I am working on another box similar to the Pelican Box. It is made out of Black Walnut Burl and Holly; it will be called the liberty box. You will have to wait until the October User Group Meeting to see it. As for after that I have nothing planned. I wait for something to pop in my head, I don’t like planning or forcing something because the design process ends up being forced too.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions